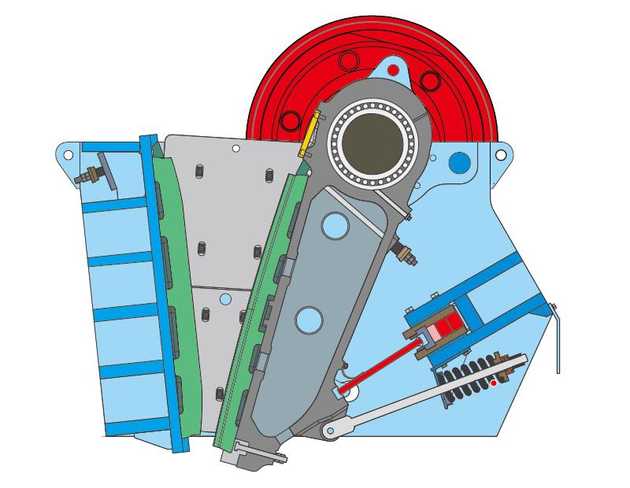

Fault phenomenon 1: The flywheel wheel swings axially to the left and right.

The reason:

- The flywheel wheel hole, flat key or shaft wears and loosens;

- The stone material is rolled into the inner side of the wheel, causing the flywheel wheel housing to crack;

- Casting defects;

- The flywheel wheel tension sleeve is loose.

Method of exclusion:

- Wear the flat key, replace the flat key, or replace the eccentric shaft or the flywheel;

- Add the flywheel guard and replace the eccentric shaft or the flywheel;

- Replace the eccentric shaft or the sheave;

- Re-tighten the tightening sleeve.

Fault phenomenon 2: The frame is crazing.

The reason:

- Casting defects or welding quality defects;

- Use of unqualified brackets and brackets, when the crusher is under strong impact, the brackets are not self-breaking, causing the frame to crack;

- The fixed jaws are not fixed Long-term ups and downs, hitting the front frame of the rack;

- The rigidity of the base of the base is poor or collapsed, the frame is beating;

- The two bolts on the bearing cover are loose;

- Fixed the movable jaws continue to be used after the tooth shape is worn;

- The direction of the weight of the flywheel wheel is misaligned due to the eccentric shaft, the pin damage or the loosening of the sleeve.

Method of exclusion:

- Remove the original crack defects, repair the repair, and replace the new frame if necessary;

- Repair or replace the new frame, and replace the original bracket and bracket pad produced by the main machine factory;

- Repair or replace the new machine Rack and fix the fixed stud bolts;

- Repair or replace the new frame, and tighten the frame foot bolts to correct the level and strengthen the foundation;

- Repair or replace the new frame and tighten the bearing cap Upper two bolts;

- Repair or replace the new frame, and replace the jaws in time;

- Repair or replace the new frame, and change the pin shaft or adjust the direction of the eccentric block to tighten the expansion sleeve.