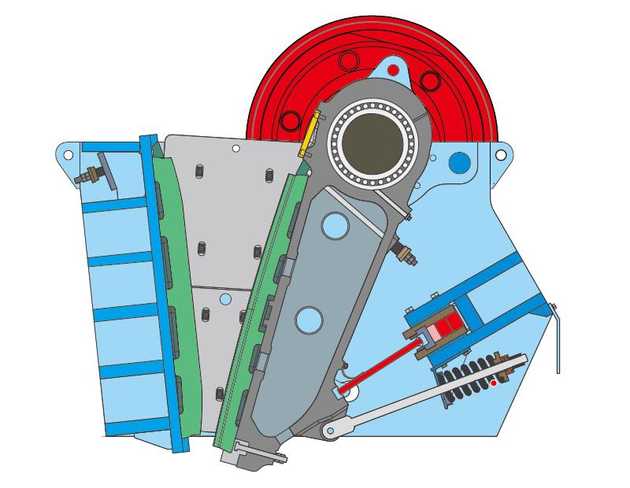

Jaw crusher is known as tiger mouth. The crushing cavity composed of two jaw plates, the movable jaw and the static jaw, completes the material crushing operation by simulating the movement of the two jaws of animals.

Advantages of jaw crusher:

- High production efficiency

The equipment has a deep crushing cavity and no dead zone, which can improve the crushing stone feeding capacity and output, save energy consumption and improve production efficiency.

- Good wear resistance

The jaw crusher parts are made of high-quality manufacturing materials, which greatly improves the pressure resistance and wear resistance of the parts. The movable jaw is made of cast steel, and the eccentric shaft is made of forged blanks. Thereby improving the reliability of the parts, making them efficient and durable.

- Adjustable discharge, more flexible

The gasket-type discharge port adjustment device is not only reliable and easy to use, but also can adjust the particle size of the crushed material.

- Easy to maintain

The jaw crusher is easy to operate, convenient and quick to maintain, and reduces downtime for maintenance.

Disadvantages of jaw crusher:

- Single crushing process

The jaw crusher cannot complete multi-dimensional crushing. If the materials to be crushed are diverse, the traditional crushing process cannot completely dissociate them, and there will be crushing phenomenon during the crushing process. And this kind of over-shredding reduces the useful components and forms waste products in the crushing operation, which will cause waste of resources and economic losses to customers.

- High energy consumption

When crushing ore with a compressive strength exceeding 245MPa, the jaw crusher will generate high energy consumption, and the advantages of energy saving and consumption reduction performance are negligible.

Therefore, under normal circumstances, jaw crushers are used as the head crushing equipment of the production line to handle the coarse crushing of various ores whose compressive strength does not exceed 245MPa.